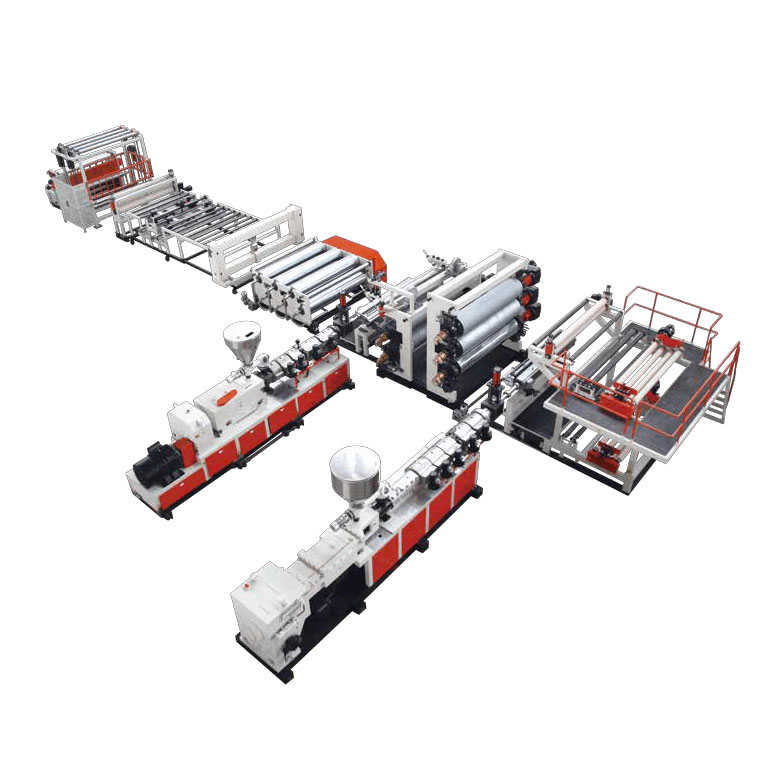

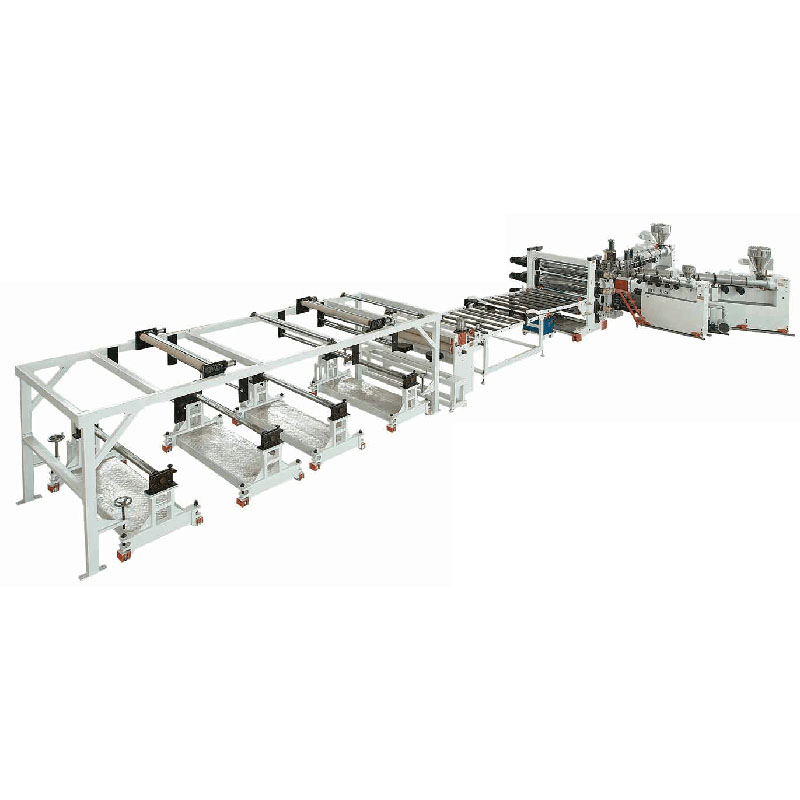

High Polymer Composite Waterproof Roll Extrusion Line

High Polymer Composite Waterproof Roll Extrusion Line Performance & Advantages

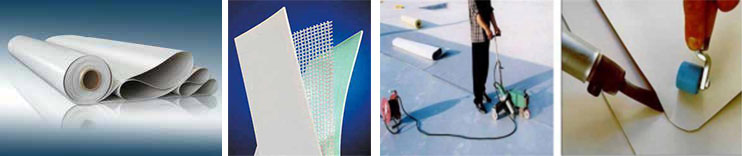

Used for different kinds of plastic material, such as PVC, TPO, PE, etc. Being able to produce the below sheets:

1. Plastic roll sheet (model: H): without coating with inner reinforced material or outer material.

2. Roll sheet with outer fiber (Model: L): coating with fiber or non-woven fabric.

3. Inner reinforced roll sheet (Model: P): Inner layer coats with polyester mesh.

4. Inner reinforced roll sheet (Model: G): Inner layer coats with glass fiber.

High Polymer Composite Waterproof Roll Extrusion Line Main Technical Parameter

| Model | Products width | Products thickness | Capacity |

| SJZ92/188-SJZ80/156 | 1200-2000mm | 0.5-3.0mm | 800-900kg/h |

| SJP130/36-SJZ92/188 | 2000mm | 0.5-3.0mm | 1200-1300kg/h |

| JWS150—JWS120 | 2000mm | 1-2mm | 1000-1100kg/h |

Waterproof Membrane Formula

The main component of the waterproof membrane is polyvinyl chloride resin, which is added in the extrusion process: plasticizer, stabilizer, titanium dioxide, modifier, etc. to form the current PVC membrane.

PVC Resin

The PVC resin used for waterproofing membrane processing is the suspension method. Depending on the raw materials used, there are two types of resins on the market.

Calcium carbide method PVC resin: The raw material is converted from coal, and there are relatively many impurities. The quality of the resin is not as good as the ethylene method, and the cost is low. Ethylene PVC resin: high purity, expensive raw materials, and high cost.

Impurities in the PVC resin may accelerate the degradation of the coil. For exposed coils with high requirements, the ethylene method is used to synthesize PVC resin.

Plasticizer

Commonly used plasticizers are DOP and DINP. Of course, there is also DOA as a low temperature-resistant auxiliary plasticizer.

DINP with the best molecular weight among the three plasticizers has the highest flash point and is the least volatile.

In practical applications, among the above three plasticizers, DINP and PVC are the least likely to migrate and volatilize from the resin after mixing and plasticizing, that is, exuding from the coil.

Stabilizer

PVC is easily degraded after heating. As long as the temperature exceeds 80 degrees Celsius, after a long time of heating, it will first decompose HCl to form a double bond.

As the decomposition accelerates, the double bonds gradually increase, and the PVC will become more and more yellow. After reaching a certain level, the PVC chain will break and the color will change from yellow to black, completely decomposing.

The function of the stabilizer is to prevent the degradation of PVC during thermal processing. Commonly used stabilizers for commercial coils are lead salts, which have good long-term thermal stability and a certain degree of self-lubricity. The only disadvantage is that lead, like heavy metal, is harmful to the human body.

Advantages Of PVC Waterproof Membrane

● Good fireproof performance: The waterproof membrane does not support burning, and has safety performances such as self-extinguishing away from the fire.

● Quick installation: the construction process is simple.

● Convenient detail processing: It is more suitable for roofing systems with many nodes and complex structures.

● Convenient maintenance and repair: reliable welding basically does not require post-maintenance, and welding repair almost does not cost.

● Good dimensional stability: fits various shapes, and the finished construction effect is beautiful and neat.

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

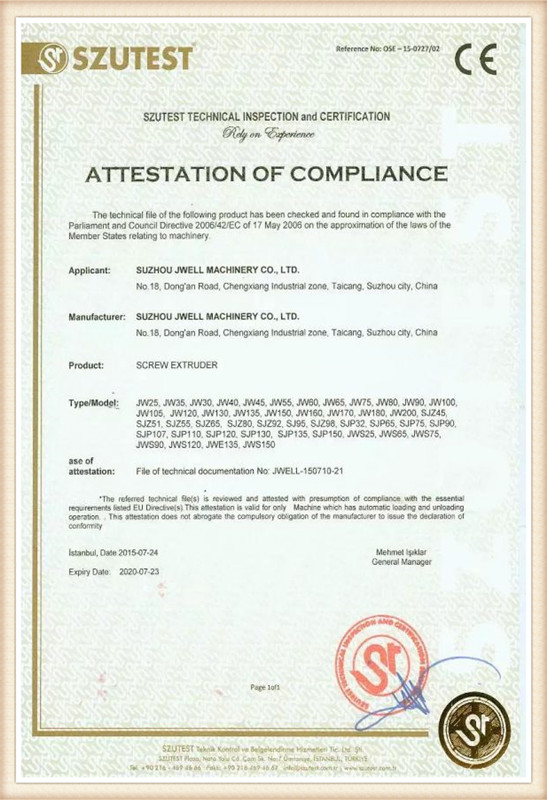

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~